We provide professionally designed automatic and semi-automatic sawing systems to achieve high-efficiency and precision material cutting. We also offer rotary angle sawing machines capable of precisely achieving 45-degree angle cuts, ensuring the superior cutting quality of both aluminum and metal materials.

-

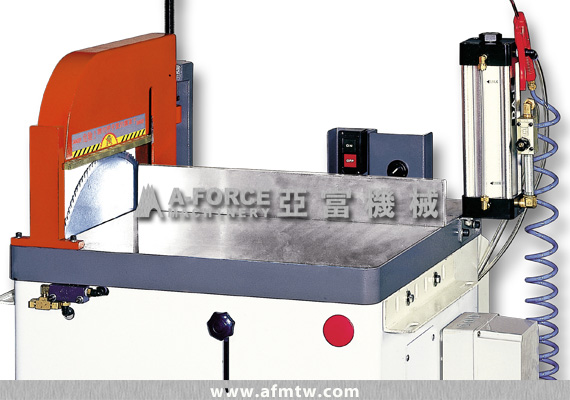

NC Circular Saw for Aluminum

- Just a simple tap on the foot pedal switch is required for the machine to automatically clamp, spray oil, and saw the material, providing both safety and ease of use.

- The hidden saw blade cuts upwards from below, allowing for the simultaneous sawing of single or multiple materials.

- Cutting is accompanied by an automatic spray of atomized cutting oil to achieve cooling and lubrication effects.

- Feed-in cutting is driven by air-over-oil propulsion, ensuring stable sawing speed.

- The machine body is finished with 200°C high-temperature baking paint, making it durable, impact-resistant, and chip-resistant.

- Capable of 90-degree and 45-degree angle cutting.

Suitable for Sawing: Aluminum, copper, heat sinks, PVC, plastic steel (PVC-U/UPVC profiles), electric boards, acrylic, carbon fiber, honeycomb board, wood, and other non-ferrous metal materials.

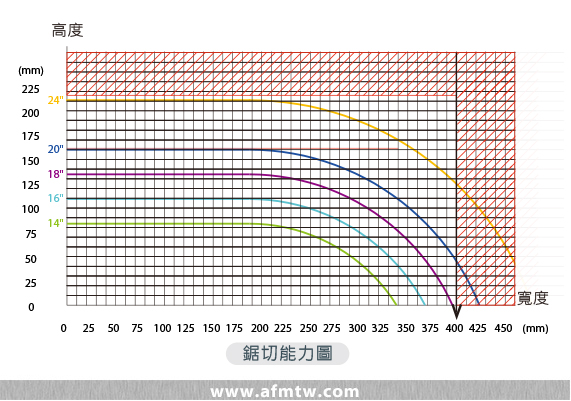

Type AF-18CA AF-18CC AF-24C Cutting Angle 90 ° or 45 ° 90 ° or 45 ° 90 ° or 45 ° Sawing Capacity: Height x Width (mm) 120 x 120, 100 x 220,

60 x 270, 20 x 300120 x 120, 100 x 220,

60 x 270, 20 x 300190 x 190, 150 x 340,

80 x 400, 20 x 450Saw Blade Speed (R.P.M.) 3200 3200 2000 Saw Blade Size 18″x1″ Bore 18″x1″ Bore 24″x1″ Bore Worktable Area (mm) 640 x 380 640 x 380 660 x 700 Worktable Height (mm) 860 860 830 Motor Power (Hp) 5 5 7.5 Required Air Pressure (kgs/cm²) 4 ~ 6 4 ~ 6 4 ~ 6 Feeding Stand Length (m) 1 ~ 7 (Optional) 1 ~ 7 (Optional) 1 ~ 7 (Optional) Machine Dimensions (mm) 840 x 800 x 1250 840 x 800 x 1250 1310 x 830 x 1460 Packing Dimensions (mm) 960 x 920 x 1450 960 x 920 x 1450 1430 x 950 x 1660 Net / Gross Weight (kgs) 300 / 380 300 / 380 480 / 580 The specifications and information on this page are for reference only and are subject to change without prior notice. Our company reserves the right to modify product designs and make revisions.

Product Images & Video

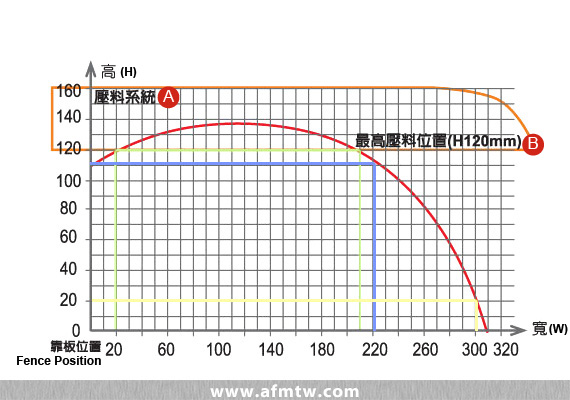

AF-18CA

A. Adjustable clamping height.

B. Adjustable cutting depth (or feed-in height). The cutting depth, clamping height, and sawing speed can be set according to the material type and height, thereby reducing idle time (or waiting time).

C. Adjustable sawing speed.

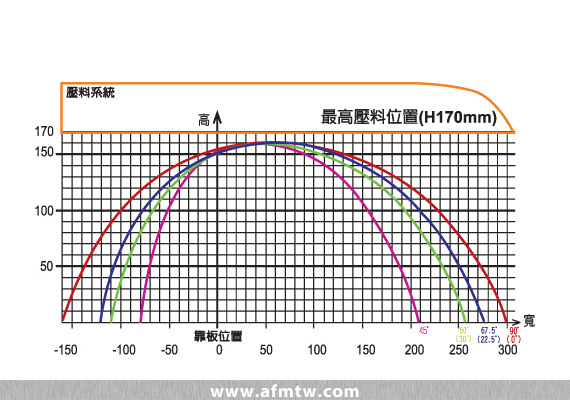

A. Clamp System

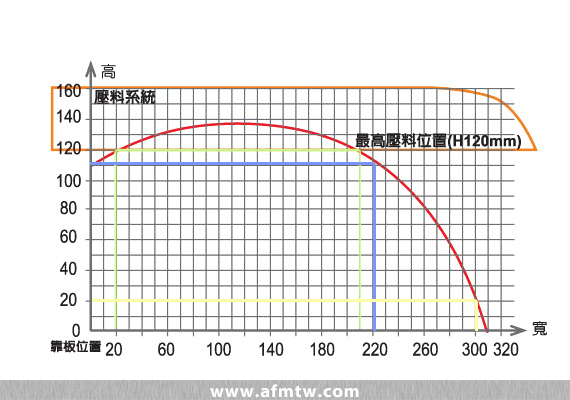

B. MAX. Clamp (H120mm)AF-18CC

A. Adjustable clamping height.

B. Adjustable cutting depth (or feed-in height). The cutting depth, clamping height, and sawing speed can be set according to the material type and height, thereby reducing idle time (or waiting time).

C. Adjustable sawing speed.

A. Clamp System

B. MAX. Clamp (H120mm)

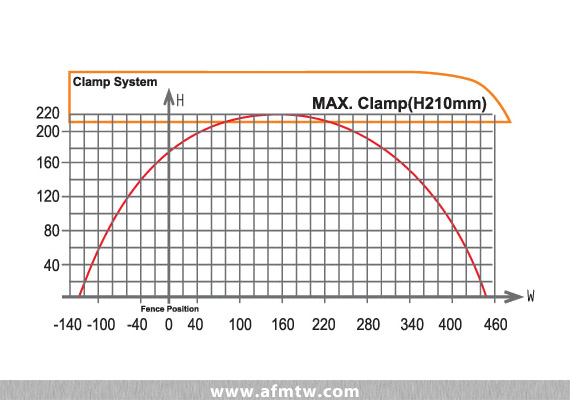

AF-24C

A. Adjustable clamping speed.

B. Adjustable sawing speed.

C. Adjustable cutting height (or sawing height).

-

Aluminum Angle Cutting Machines

- Operation & Safety: The machine operates with a simple footswitch to engage automatic clamping and sawing. The hidden saw blade cuts upwards from below, allowing for simultaneous sawing of single or multiple materials. This design ensures superior safety by keeping hands away from the blade.

- Stability & Control: The clamping system and sawing system are controlled by separate, independent pneumatic cylinders. This allows for the adjustment of clamping speed and sawing speed based on material type, thereby achieving highly stable cutting results (enabling fast and steady material sawing). Additionally, the clamping system ensures materials are held completely and tightly secured.

- Material Protection: Clamping pressure can be individually adjusted based on material type to prevent damage caused by excessive force.

- Maintenance & Efficiency: The automatic oil spraying system is a forced lubrication system, which significantly enhances lubrication and cooling effects while reducing the failure rate.

- Adjustability: The clamping height and protective cover height are adjustable.

- Angle Cutting: Suitable for angular sawing, processing angles from 0 to 45 degrees (or 45 to 0 degrees) and 90 degrees. A handheld handle allows for easy rotation of the workbench to adjust the sawing angle.

Type AF-20 AF-20-24 AF-20-30 Cutting Angle +45° ~ 0° ~ -45° +45° ~ 0° ~ -45° +45° ~ 0° ~ -45° Saw Blade Speed (R.P.M.) 3000 2000 1500 Saw Blade Size 20″x1″ Bore 24″x1″ Bore 30″x50mm Bore Worktable Area (mm) 920 x 650 1140 x 750 1327 x 640 Worktable Height (mm) 875 920 1070 Motor Power (Hp) 7.5 7.5 10 Required Air Pressure (kgs/cm²) 4 ~ 6 4 ~ 6 4 ~ 6 Machine Dimensions (mm) 1200 x 1090 x 1780 1480 x 1350 x 2100 1660 x 1400 x 2210 Packing Dimensions (mm) 1320 x 1210 x 1980 1600 x 1470 x 2260 1780 x 1520 x 2300 Net / Gross Weight (kgs) 500 / 610 800 / 920 1300 / 1500 The specifications and information on this page are for reference only and are subject to change without prior notice. Our company reserves the right to modify product designs and make revisions.

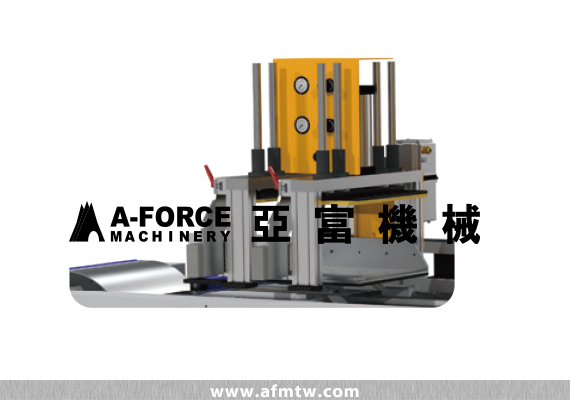

AF-20 series Product Images

A. Adjustable clamping speed

B. Clamping system is controlled by an independent air cylinder.

C. Adjustable clamping height.

D. Adjustable cutting speed.

E. Clamping system mover on linear quide way, that stable clamping.

F. Hold handle for rotary worktable angular. ( ± 0 ~ 45 degrees )

G. Accurately controlled oil mist system greatly improves lubrication and cooling effect, while reducing trouble to a minimum.

H. The handle for convenient and easy fix worktable.

A. Clamp System

B. MAX. Clamp (H120mm) -

Automatic Slotting Machine

- Automatic feeding, positioning, oil spraying, grooving (slotting), and sawing functions.

- Horizontal saw blade cutting, suitable for processing wider and larger materials.

- Utilizes a servo motor to drive a ball screw (or high-precision ground rack and pinion) for high accuracy.

- Features CNC control interface for easy operation.

- Oil pressure is used for feed-in cutting, resulting in high cutting stability.

- Allows for up to 100 sets of memory size settings, with a maximum of 12 sizes per set.

- The computer automatically records the time and quantity required for each process, serving as a basis for calculating processing costs.

- The machine automatically senses the tail material during processing, or offers an optional feature for self-setting tail material length.

- Materials can be placed in parallel and stacked for sawing.

Type AF-NC18SM Automatic Slotting Machine Servo Drive System Ball Screw / High-Precision Ground Rack and Pinion Sawing Capacity (mm) 200 x 200 , 175 x 210, 130 x 350, 20 x 400

(Varies based on blade size)Automatic Feeding Stroke (mm) 1350 mm (3000 / 6000 mm Optional) Bidirectional Feeding Automatic Feeding Accuracy (mm) ±0.1 Saw Blade Spindle Speed (R.P.M.) 1500 - 3500 Stepless Speed Regulation (Set according to blade size) Saw Blade Spindle Motor (HP) 10 Spindle Inverter Motor (HP) 10 (Optional 15) Hydraulic Feed Motor (HP) 1 Servo Motor Power (Kw) 1 Touch Screen / HMI (inch) 5.7″ Saw Blade Size (inch) Choice of 12", 14", 16", 18", 20", 22", 24" (1" Bore) Required Air Pressure (kgs/cm²) 4 ~ 6 Machine Dimensions (mm) 3500 x 2100 x 1860 Packing Dimensions (mm) 3620 x 2220 x 2000 Net / Gross Weight (kgs) 2300 / 2700 The specifications and information on this page are for reference only and are subject to change without prior notice. Our company reserves the right to modify product designs and make revisions.

AF-NC18SM Automatic Slotting Machine Product Images

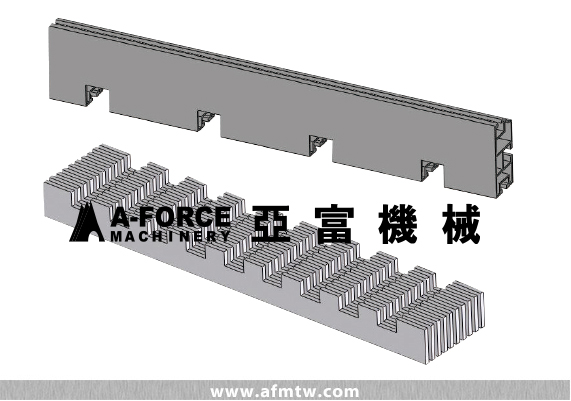

- The feeding table is equipped with two sets of top clamps and two sets of side clamps. - Suitable for sawing irregularly shaped materials. - Without the need for custom fixtures. - Workpiece is held securely in place.

- Allows for automatic setting of the grooving position and grooving width (or slotting depth). - Features a dual function of grooving (slotting) and sawing. - Servo motor controls the precise setting of the saw blade's ascent position.