We provide professionally designed automatic and semi-automatic sawing systems to achieve high-efficiency and precision material cutting. We also offer rotary angle sawing machines capable of precisely achieving 45-degree angle cuts, ensuring the superior cutting quality of both aluminum and metal materials.

-

Automatic Slotting Machine

- Automatic feeding, positioning, oil spraying, grooving (slotting), and sawing functions.

- Horizontal saw blade cutting, suitable for processing wider and larger materials.

- Utilizes a servo motor to drive a ball screw (or high-precision ground rack and pinion) for high accuracy.

- Features CNC control interface for easy operation.

- Oil pressure is used for feed-in cutting, resulting in high cutting stability.

- Allows for up to 100 sets of memory size settings, with a maximum of 12 sizes per set.

- The computer automatically records the time and quantity required for each process, serving as a basis for calculating processing costs.

- The machine automatically senses the tail material during processing, or offers an optional feature for self-setting tail material length.

- Materials can be placed in parallel and stacked for sawing.

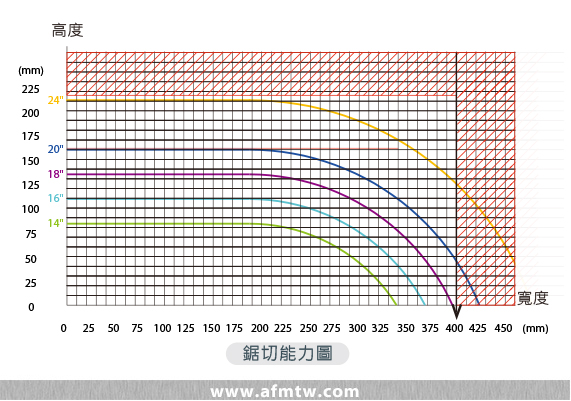

Type AF-NC18SM Automatic Slotting Machine Servo Drive System Ball Screw / High-Precision Ground Rack and Pinion Sawing Capacity (mm) 200 x 200 , 175 x 210, 130 x 350, 20 x 400

(Varies based on blade size)Automatic Feeding Stroke (mm) 1350 mm (3000 / 6000 mm Optional) Bidirectional Feeding Automatic Feeding Accuracy (mm) ±0.1 Saw Blade Spindle Speed (R.P.M.) 1500 - 3500 Stepless Speed Regulation (Set according to blade size) Saw Blade Spindle Motor (HP) 10 Spindle Inverter Motor (HP) 10 (Optional 15) Hydraulic Feed Motor (HP) 1 Servo Motor Power (Kw) 1 Touch Screen / HMI (inch) 5.7″ Saw Blade Size (inch) Choice of 12", 14", 16", 18", 20", 22", 24" (1" Bore) Required Air Pressure (kgs/cm²) 4 ~ 6 Machine Dimensions (mm) 3500 x 2100 x 1860 Packing Dimensions (mm) 3620 x 2220 x 2000 Net / Gross Weight (kgs) 2300 / 2700 The specifications and information on this page are for reference only and are subject to change without prior notice. Our company reserves the right to modify product designs and make revisions.

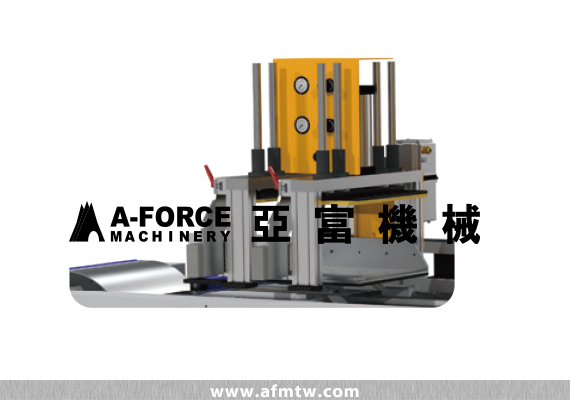

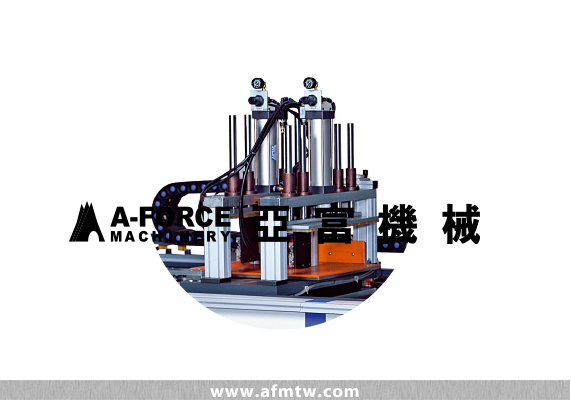

AF-NC18SM Automatic Slotting Machine Product Images

- The feeding table is equipped with two sets of top clamps and two sets of side clamps. - Suitable for sawing irregularly shaped materials. - Without the need for custom fixtures. - Workpiece is held securely in place.

- Allows for automatic setting of the grooving position and grooving width (or slotting depth). - Features a dual function of grooving (slotting) and sawing. - Servo motor controls the precise setting of the saw blade's ascent position.

-

Automatic Slotting Machine

- Automatic feeding, automatic positioning, automatic oil spraying, and automatic grooving (slotting).

- Horizontal saw blade cutting, suitable for processing wider and larger materials.

- Utilizes a servo motor to drive a ball screw (or high-precision ground rack and pinion) for high accuracy.

- Features CNC control interface for easy operation.

- Oil pressure is used for feed-in cutting, resulting in high cutting stability.

- Allows for up to 100 sets of memory size settings, with a maximum of 12 sizes per set.

- The computer automatically records the time and quantity required for each process, serving as a basis for calculating processing costs.

- The machine automatically senses the tail material during processing, or offers an optional feature for self-setting tail material length.

- Materials can be placed in parallel and stacked for sawing.

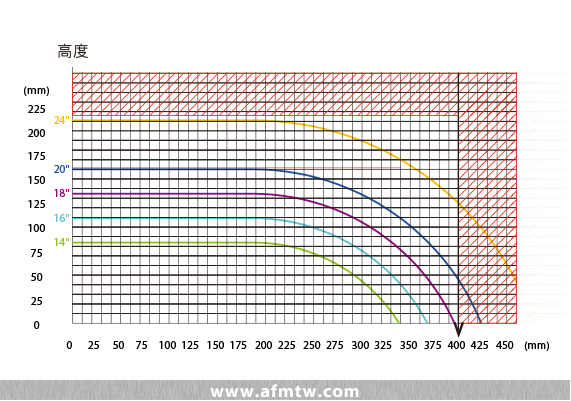

Type AF-NC18SM Groove Cutting Machine Automatic Feeding System Servo Motor with Ball Screw Drive (Optional Cutting Function - Upper and Lower Axis) Grooving / Slotting Function Grooving / Slotting Stroke Width 400 mm

Grooving / Slotting Depth 50 mm (Height set via Touch Screen)

Adjustable Grooving / Slotting Width (Touch Screen)Grooving Depth Drive Servo Motor 1W Saw Blade Size 12”~14” Worktable Height 918mm Max. Single Feed Stroke 1,250 mm (Bidirectional Feeding Available) Automatic Sawing Accuracy ±0.15 mm Spindle Speed 1,500~3,600 R.P.M.

(Adjustable with Inverter)Spindle Motor 10 HP (4P) Hydraulic Motor 2 HP Air Compressor Motor 4–6 kgs/cm² Machine Dimensions 3,830 x 2,175 x 1,750 mm Machine Weight 1,823 kgs The specifications and information on this page are for reference only and are subject to change without prior notice. Our company reserves the right to modify product designs and make revisions.

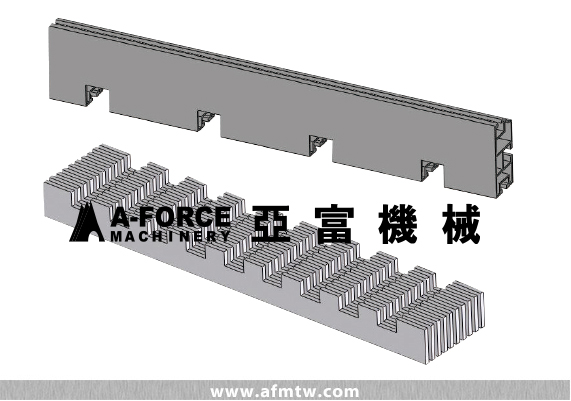

AF-NC18SM Groove Cutting Machine Product Images

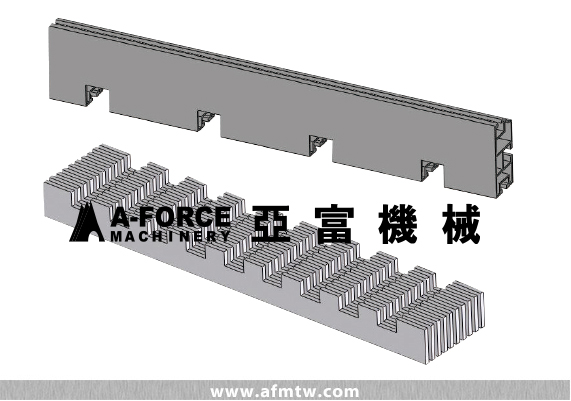

- The feeding table is equipped with two sets of top clamps and two sets of side clamps. - Suitable for sawing irregularly shaped materials. - Without the need for custom fixtures. - Workpiece is held securely in place.

- Allows for automatic setting of the grooving position and grooving width (or slotting depth). - Features a dual function of grooving (slotting) and sawing. - Servo motor controls the precise setting of the saw blade's ascent position.