- Automatic feeding, positioning, oil spraying, grooving (slotting), and sawing functions.

- Horizontal saw blade cutting, suitable for processing wider and larger materials.

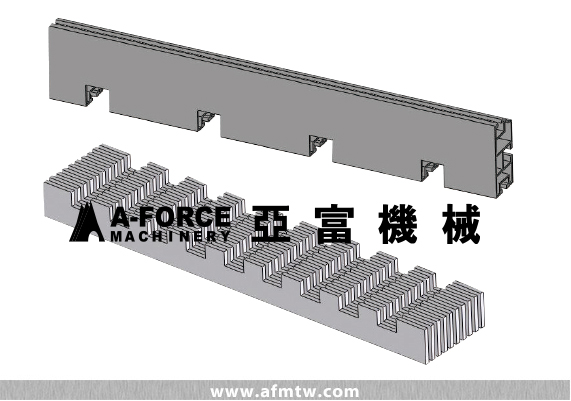

- Utilizes a servo motor to drive a ball screw (or high-precision ground rack and pinion) for high accuracy.

- Features CNC control interface for easy operation.

- Oil pressure is used for feed-in cutting, resulting in high cutting stability.

- Allows for up to 100 sets of memory size settings, with a maximum of 12 sizes per set.

- The computer automatically records the time and quantity required for each process, serving as a basis for calculating processing costs.

- The machine automatically senses the tail material during processing, or offers an optional feature for self-setting tail material length.

- Materials can be placed in parallel and stacked for sawing.

| |

| Type | AF-NC18SM Automatic Slotting Machine |

| Servo Drive System | Ball Screw / High-Precision Ground Rack and Pinion |

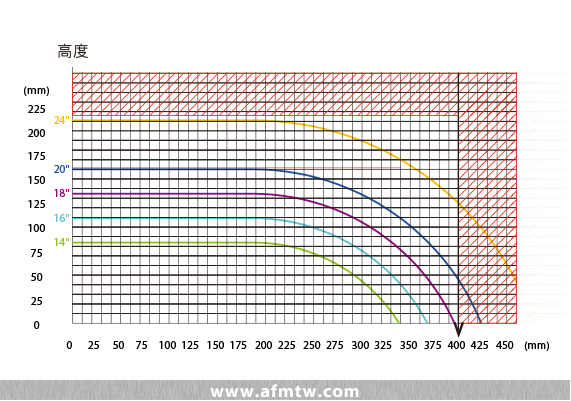

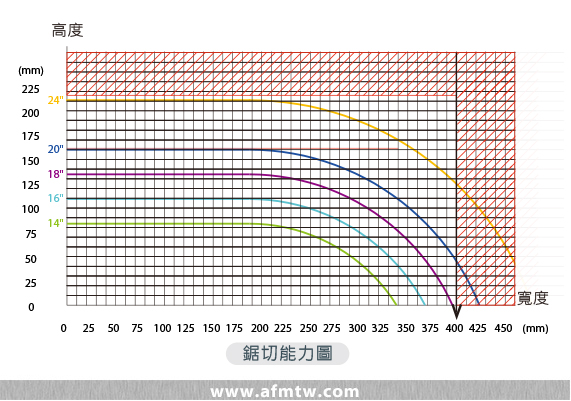

| Sawing Capacity (mm) | 200 x 200 , 175 x 210, 130 x 350, 20 x 400 (Varies based on blade size) |

| Automatic Feeding Stroke (mm) | 1350 mm (3000 / 6000 mm Optional) Bidirectional Feeding |

| Automatic Feeding Accuracy (mm) | ±0.1 |

| Saw Blade Spindle Speed (R.P.M.) | 1500 - 3500 Stepless Speed Regulation (Set according to blade size) |

| Saw Blade Spindle Motor (HP) | 10 |

| Spindle Inverter Motor (HP) | 10 (Optional 15) |

| Hydraulic Feed Motor (HP) | 1 |

| Servo Motor Power (Kw) | 1 |

| Touch Screen / HMI (inch) | 5.7″ |

| Saw Blade Size (inch) | Choice of 12", 14", 16", 18", 20", 22", 24" (1" Bore) |

| Required Air Pressure (kgs/cm²) | 4 ~ 6 |

| Machine Dimensions (mm) | 3500 x 2100 x 1860 |

| Packing Dimensions (mm) | 3620 x 2220 x 2000 |

| Net / Gross Weight (kgs) | 2300 / 2700 |

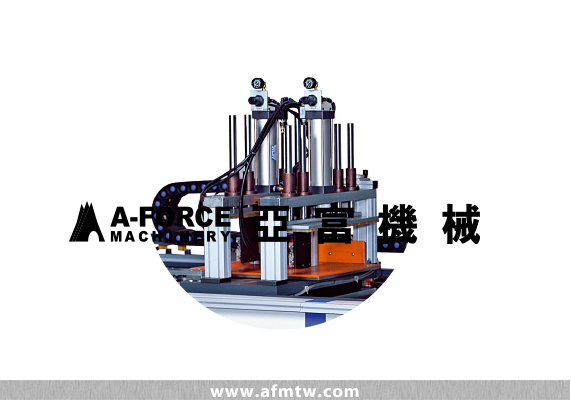

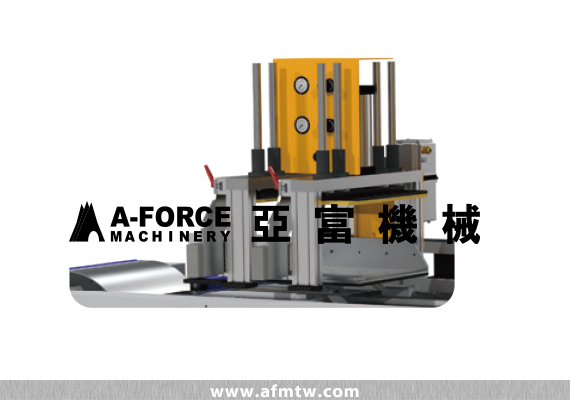

AF-NC18SM Automatic Slotting Machine Product Images

- The feeding table is equipped with two sets of top clamps and two sets of side clamps. - Suitable for sawing irregularly shaped materials. - Without the need for custom fixtures. - Workpiece is held securely in place.

- Allows for automatic setting of the grooving position and grooving width (or slotting depth). - Features a dual function of grooving (slotting) and sawing. - Servo motor controls the precise setting of the saw blade's ascent position.